Businesses of all types and sizes are fairly reliant on computers and servers these days.

From data storage to simply running an internal office network, servers have become a fair staple in just about any industry.

These servers have their own sets of requirements, however, if they are to be used and looked after properly; one such requirement to have them housed in cooled server rooms, which means that these businesses also have a need for specialised refrigeration and airconditioning repair and maintenance services, and of course, services relating to their installation in server rooms.

Here we will discuss what makes a cooled server room an essential investment for just about any business. We will do this by looking at what they are exactly, which businesses make the most use out of them, why they are needed, as well as their benefits.

This will help your business take the right approach to cool its server room; so, let’s get started:

What are Cooled Server Rooms?

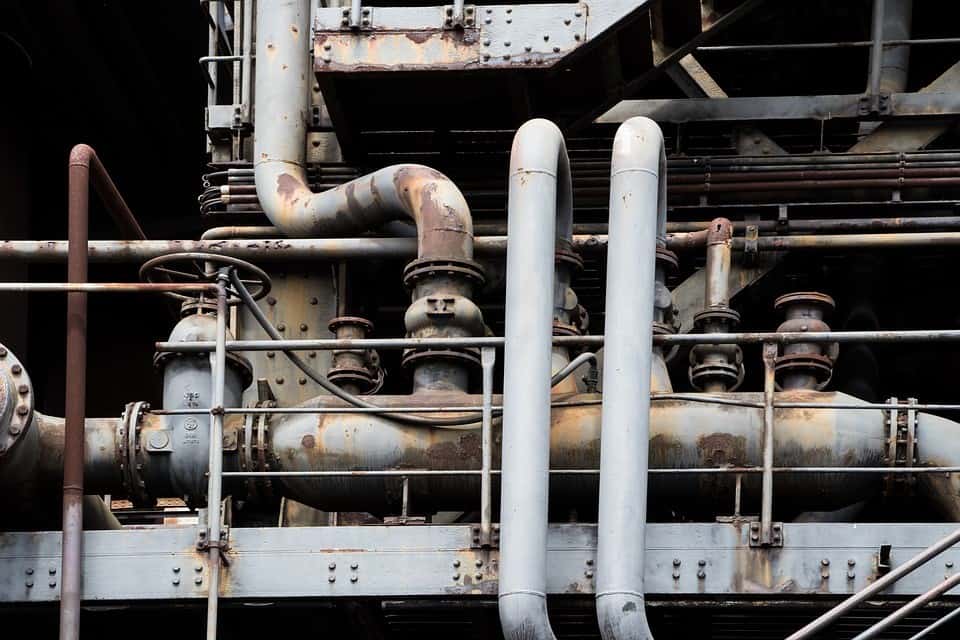

Cooled server rooms essentially provide an environment that ensures the protection and longevity of computer server systems.

The hardware that the house produces a lot of heat, and as the needs for this hardware increases in scale, the heat generated by these system increases as well.

The challenge here is that computer systems and heat are two things that typically don’t go very well together, especially when temperatures start to be generated in excessive levels (which is often the case with servers).

This means that server rooms need to have carefully implemented climate control systems that don’t only keep a constantly cool temperature, but also ensure a certain humidity level that is neither too moist or too dry.

To ensure this, server rooms are fitted with specialised air conditioning systems that allow for pinpoint control over their internal climate variables (such as temperature and humidity).

This doesn’t just offer a number of advantages to server rooms (which we will discuss a little bit later on) but is actually a necessity for keeping servers running effectively, without downtime suffered from avoidable damages.

On top of this, server rooms are lockable to keep equipment secure and are generally also fire-proof to ensure that there is a minimal risk of damage caused.

Who Needs Them?

Server rooms come in all shapes and sizes, from compact shelves with single servers to entire refrigerated rooms housing millions of Rands worth of sensitive equipment.

The scale and complexity of cooled server rooms is dependant on the size and requirements of the business using it, making them essential for just about any type of business.

Data Storage Handling

Any business working with data storage and handling generally make use of expensive, highly specialised electronic equipment.

This is as true for data-centres and media houses as it is for large-scale companies that need to store large quantities of client data on electronic equipment.

In such professional settings, the equipment used to store, analyse and retrieve data is the cornerstone of the business using them, and as such, need exceptional care if these types of businesses are to remain in a competitive space; regardless of the size of their operations.

Medium to Large Businesses

Businesses of just about all sizes are reliant on cold server rooms as well, and the more they scale up, the more complex the needs for these server rooms become.

Exceptionally small businesses, whose server may only be a single computer, could probably get away with not having a proper server room or bracket in place. But as operations grow through medium businesses, servers become significantly more complex; and switches, routers, computers and hard0drive shelves start being used.

By the time any business’ tech reaches this stage, the use of a cooled server room that keeps servers and their various components becomes all the more essential.

Why do Server Rooms Need Cooling?

We’ve spoken a bit about the fact that servers need effective cooling solutions; but why exactly do they.

Electronic equipment is highly sensitive to both temperature and ambient moisture in their immediate environment; and while they run, they actually add to the negative variables that can affect their performance or even leave them damaged.

Because of this, there are two major factors that every server setup needs to ensure are carefully controlled.

These factors include temperature and humidity:

Temperature Control

Temperature is an essential point of control wherever computers and their related server equipment is being employed. As they run (and depending on the processing power required for their tasks), enough heat can be generated to actually cause damage to equipment.

In any setting where electronic equipment exceeds temperatures of 90°C, there is a serious risk of failure.

This means that ambient temperatures need to be kept at a respectable minimum, to help with cooling equipment while it is being used.

The greater the processing power, the greater the need for cooling. The greater the need for cooling, the more effective cold server room needs to be.

Humidity Control

Humidity is another concern for cold server rooms since electronic equipment is highly sensitive to excessive moisture in the environment.

It is no secret that water and electronics are not exactly the best of friends, and so humidity levels need to be kept relatively low to ensure that no excessive moisture in the server room presents a risk of damage to equipment.

This doesn’t mean, however, that cold server rooms should be as dry as possible, as too little moisture can create an even greater problem.

If the air in a cold server room becomes too dry, there is a heightened risk of static charges being created on its surfaces.

Electronics are even more sensitive to static charges than they are to moisture, with even the smallest sparkrendering hardware utterly unusable.

Because of this, col server rooms need to find the ideal balance between moisture and dryness in the air.

To offer the best protection possible, the relative humidity in a server room should be somewhere between 40% and 60%.

Other Essential Server Room Requirements

Of course, server rooms fulfil a number of other functions aside from temperature control, which means that their design needs to incorporate a few essential elements at once.

Most important of these include the need for a solution that is relatively fire-proof, it needs to be able to prevent tampering and pilfering, and it also needs to accommodate enough space for every component being used as part of the server, while still offering optimal airflow.

Let’s take a closer look at each one here:

Fire Proof

Let’s go back quickly to the way that electronics and water are never a good mix for each other, and then consider how one would go about dousing a fire should it be in danger of reaching the server room.

Naturally, fire sprinklers and other suppression systems are not a good fit for server rooms because of this.

Therefore, they need to be designed in such a way as to offer exceptional fire protection, to ensure that there is a minimal risk of damage should one break out in the office.

Security

The next important thing to consider is server room security, and every server room or shelf needs to offer exceptional protection in this regard.

Consider the total cost of every piece of equipment within your server room; not just the cost of replacing them should something happen, but the value of their functions and the data they store for your business.

A loss of this equipment, or its functionality, as a result of tampering with the hardware or worse still, having it stolen, can present a possibly fatal challenge to businesses of all types; particularly those that house sensitive information.

Because of this, server rooms need to be easily secured with locks, surveillance and alarm systems that deter theft or tampering.

Available Space

Where the availability of space is a concern for server rooms, there are two things that need to be seen for them to work effectively and to ensure the longevity and performance of its contained hardware.

Firstly, it stands to reason that the room needs to be large enough to accommodate every component that makes up the server. These might include computers, screens, external hard-drive cases, network switches, monitoring hardware, routers and more.

So, the first step when having one designed is to know exactly what type of hardware it will need to encase so that they can be designed to accommodate them comfortably.

This doesn’t mean that as much hardware as possible can be crammed into a server room, you need to remember that cold server rooms only operate effectively when there is enough air flowing through them to cool components and expel any heat generated by them.

Because of this, they need to be designed with accommodation for additional space.

Should the needs of your server be scaled up, it might be worth increasing the capacity of your server room before upgrading the server itself.

The Benefits of Cooled Server Rooms for Businesses

With all of this in mind, you should already be able to see how server rooms can benefit your business.

But let’s take a bit of a closer look at some of the most major advantages that can be gleaned from doing so.

These include the ability to keep equipment properly protected, the ability to fine-tune energy consumption, the ability to easily scale your server rooms for your particular needs, and extending the life-span of your server-related hardware.

Protect Equipment

Server hardware faces a number of dangers from a variety of sources including static, moisture, heat, theft, fire, surges, and accidents; just to name a few.

While the hardware used is generally quite robust, they do require additional protection, especially as they grow in scale and complexity.

The carefully controlled environment offered by cold server rooms ensures that any risks to your hardware are minimised, thanks to their effectiveness at protecting hardware from damage through all of the sources mentioned above.

Fine-Tune Energy Consumption

If energy consumption and running costs area concern for your business, it is good to know that a properly designed server room allows for not only careful and thorough monitoring of the conditions in the room (such as humidity and temperature), but also gives you exact control over those variables as well.

This allows businesses to find a balance between fostering a protective environment for the server room, while also ensuring that running costs are kept at a minimum.

Scalability

As your business grows and changes, so too will it’s particular needs, and one of the first places where you might need to make adjustments in this regard includes your company’s server.

While server rooms are complex and specifically designed to fit particular business environments, they are generally not set-in-stone.

They are generally designed to be easily adapted to the growth of a business, as the requirements for hardware and performance increases alongside the capacity of the business itself.

Extend Equipment Longevity

Excessive heat in a server room may not necessarily damage equipment immediately. Often enough, excessive temperatures simply result in a significant shortening of the hardware’s lifespan.

Depending on the severity of the setting, hardware’s lifespan can be shortened by anything between months to years.

By providing the ideal climate for hardware to operate in, therefore, you can significantly extend the years of use your business gets out of them.

Contact Centromac South Africa for Details

Hopefully, this information has helped to make things a little clearer for you if your business is looking for assistance with setting up a cold server room that suits its needs the best.

If you would like to know more about our offers on cold server installations, maintenance and repairs, be sure to get into contact with a representative from CentromacSouth Africa today, or visit our website for further details on our offers.